Rig on a Brig

Introduction to Rigging

Have you ever sailed on a tall ship? Felt the consistency of those offshore winds? Have you ever heard the rig humming as the vessel takes on the element of a brisky weather? Experienced that gentle tilting as she gracefully gives in on the swell? How many times hauling, hoisting and heaving was part of the experience? Roughed ropes and three hour sleep as a main course. Blisters and bruises to drink. And the salty sea water for a dessert! ... Naaahh ... I haven’t done any of that ;-)

Our polish shipwright Artur in front of Ceiba’s stem

But tell you what: I design the rigging for our SAILCARGO INC. vessel Ceiba. Yup, just took off with this endeavour some two weeks ago. Which is a great honour by the way. To tackle such an engaging jobby. And this “article” is a trifling introduction to it. Let’s get on with it, ‘ey?

My name is Artur Ryszard Mrukowski and happen to be one of the old yardies. Been here at AstilleroVerde for … erm… Keel and over fifty frames now (yes, I know… time can take a subjective and abstract form). For the purpose of this publication my experience enhances vastly sail racing. Multiple wins in different classes and rating formulas (both traditional and modern) over the years gave my boss the confidence to trust me with this task in particular. Collaboration with Danielle Doggett (tall ship rigger and SEO of SAILCARGO INC.) and Mark Shiner (sail designer) also gives extra kick off assurance that we all do the right job.

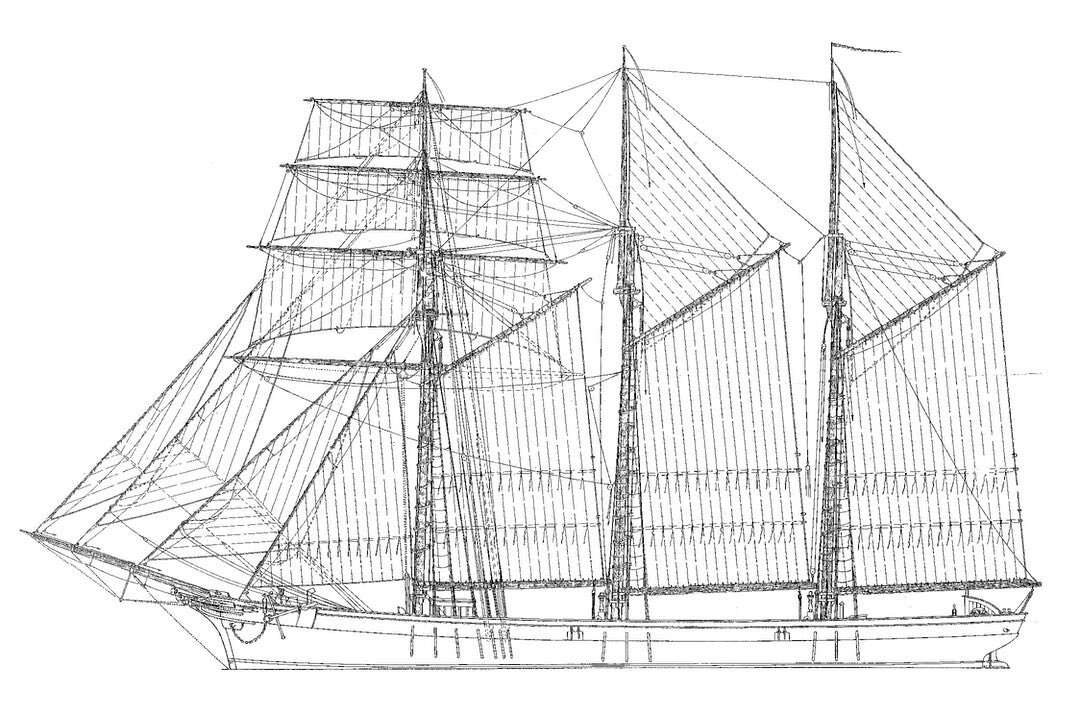

Some tech talk: Ceiba is a three masted, square top sail schooner. For some of you, unfamiliar with terminology of tall ship rigging, it would mean that the vessel we are focusing on here has three masts with gaff type sails on them. The fore most one of which is rigged with square type sails on top. If that makes any sense to you at all ;-)

She will carry around 587m2 of primary canvas (sail area). Then we can talk stun sails, fisher mans (optional and additional types of sails) etc. Her masts reach just about twenty eight meters high above water line and weight sequentially 2.2 tons – fore mast; 1.5 ton – main mast and 1.5 ton mizzen mast. The perky bowsprit will be sticking out eight meters beyond her bow and Ceiba’s Length Over All (L.O.A.) is forty eight meters.

Those are „The Big Numbers”. But how it is all done? How is the whole process of designing the rigging conducted? And what is my part in all that?

Ceiba’s preliminary rigging diagram (prior to present designing stage)

So we grabbed a phone, dialled the naval architect’s number and asked: “Hey, Mr architect. Would you be so kind and provide us with the spar lengths please so we can start to calculate?” He said sure, most certainly and a second later we’ve had the information necessary in our mailbox.

From then on it has been my part having to work with the sail plan in 1:50 scale. On that very plan I would measure and draw all the required lengths of ropes which will be used to man and handle the sails hence the whole ship. But before that happens our team needs to be absolutely sure that given rigging solution is the right one in the right spot. When it comes to rigging I resonate with ergonomy, simplicity and most of all functionality. Ceiba has a very specific function indeed. She is a cargo vessel and it will be her principal task to carry up to 250 tons of merchandise and produce. That factor is our main objective in designing the running rigging (all the adjustable ropes, cables and/or chains, which are in constant use, to trim the yards and sails). Sometimes it takes quite some time to consider, imagine the layout (on deck/mast) and process different configurations of block systems and pulleys which would move spars and trim sails. Another guideline regards handling the cargo in port. Ceiba has two cargo hatches and will be fully independent in loading and unloading her goods. She will have three cargo booms at her disposal and to operate those also requires designing pulley systems. Which ultimately need to “live” in symbiosis with the rest of the rigging when under sail.

When the designing part is done and the team has decided on what we need, what we can and what is right, I then start to measure lengths of every single rope of the running rigging. So at instance the length of the rope required to hoist (to raise a body, sail, spar, flags, pendants by the assistance of tackles or single block) the throat (the widened and hollowed end of gaff next to mast; opposed to peak, the outer end) of the mizzen (fore-and-aft sail set on mizzen mast, also called spanker or driver) gaff spar (a spar (cylindrical wood) used in ships to extend the heads of fore-and-aft sails which are not on stays) is sixty five meters off base and another eleven meters for the “jig”, which is additional purchase to add extra tension, if required. All together to handle the mizzen sail only will take 330 meters of 7/8 in. rope.

The next stage is to count all these blocks, sheaves and pulleys we have been “imagining” this far. Of course those have to be of suitable and sufficient size, etc. When estimating lengths and blocks is finished, the inquiries will be made and orders placed. The team is not there yet and here we focus only upon the introduction to rigging stage of the build. We are confident to establish a whole rigging facilities on site. Our AstilleroVerde shipyard will courageously assemble entire standing rigging (all the fixed ropes, wires and cables which support and reinforce masts), running rigging, and manufacture fittings and metal works for Ceiba.

More updates regarding the assembly process to come.

Rigging calculations for sailing cargo ship AVONTUUR, done by Danielle Doggett.